Interested in learning more?

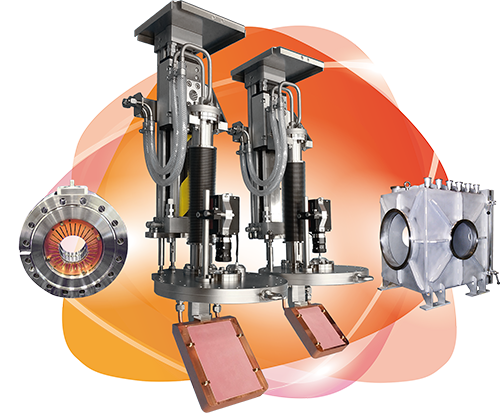

High-Quality Accelerator-Related Equipment

Princeton Scientific Corp. supplies products and services to the accelerator scientific community.

Our areas of expertise include beamline systems, beam diagnostic devices for research-, industrial-, and commercial accelerator systems. We specialize in designing accelerator-related equipment. Our many industry contacts such as scientists & engineers all over the world – support commitment to innovation, quality, and customer satisfaction. We provide end to end design, engineering and integration solutions to scientists worldwide. Our Faraday Cups, Beam Stoppers, Beam Profile Measurement Systems and UHV Linear and Rotating Feedthroughs are well known within the scientific community.

Please find available products and designs. Provide us with detailed drawing for pricing of special custom designs.

Vacuum Chambers

Cylindrical or rectangle UHV chambers are used for installation of beam diagnostic devices, vacuum gauges, electrical feedthroughs, and pumping aggregates. The distance between supporting flanges and beam axis should be uniform after optimization of various components, that must be attached. Universal elements such as compressed air actuated feedthroughs for example, can be designed with identical stroke and are subsequently exchangeable along the accelerator line.

Metal-Ceramic Bonds

Ceramic chambers are widely used in accelerator units for injection, fast extraction and beam excitation. These alumina chambers are placed in fast pulsed (range of nanoseconds) electromagnets of the kicker, bumper, dumper or scanner application. The reason for applying ceramic chambers is to avoid shielding of a fast changing external magnetic field by metallic chamber walls and to avoid heating, due to eddy currents. To prevent accumulation of static charges and to reduce secondary electron emission on the ceramic surface the internal surface has to be coated by a thin low conductive layer.

High Vacuum Feedthroughs

Universal precision high vacuum feedthrough with an accuracy of positioning of +0.03mm (single or twin version). The subject feedthrough is provided for the linear translation of elements inside a high-vacuum system. The universal feedthrough allows for mounting of arbitrary elements at the bottom of the spindle (inside the vacuum). Cooling of the attached elements is possible through the bore of the spindle. In the field of accelerator technology, our universal feedthrough is useful for assembly of slit systems, emittance measurement devices, scanners and frequency tuners.

Beam Profile Measuring System

For measurement of intensity distribution of an accelerated ion or electron beam in two transverse directions (X and Y). Optional grids are available that permit measurement of additional planes. Principle: wires to be used for X and Y planes collect charged particles; the collected charge is then converted to a given energy level, which represents beam profile intensity.

Configuration of Complete System:

Configuration of Complete System:

- Compressed air actuated high vacuum feedthrough (permits harp to move ‘in’ and ‘out’ of the beam path)

- Harp and frame with adapter (permits unit to be connected to compressed air actuated feedthrough)

- Signal processing electronics

Emittance Measurement Device

The device consists of precision high-vacuum feedthrough, detectors assembly with emittance measurement chamber, and slit/ detector assembly. Via a narrow slit, part of the beam is selected for measurement. Behind the slit, a detector system is positioned, permitting measurement of beam divergence for the selected bundle. This is accomplished by means of current measure-ment on the multistrip collector array.

Variable Segmented Aperture

The variable segmented aperture fits into the entrance ports of vacuum chambers for:

- Beam size limitation

- Rough estimation of beam position

- Using an appropriate hardware interlock system, accelerator components can be protected against incorrect beam adjustment.

Beam Stopper

The beam stopper is provided to collect accelerated particles and can be mounted on the end of a beam line or on the down-stream flange of a standard diagnostics chamber.

Capacitive Pick-Up Probes

The capacitive pick-up probe is used for observation of the particle beam micro-structure of RF-accelerators. The probe should be followed by a broadband signal processing system. The pick-up signals may be used to observe the shape of bunches, as well as to measure the position of bunches in time, with reference to a RF-signal.

Faraday Cups

For measurement of mean beam current of particle accelerator we offer cooled, uncooled or coaxial Faraday Cups. Accelerated particles (high energy primarily) are stopped in the cup and an electric charge is detected as corresponding electric current. The Faraday Cup may be moved into the beam by means of an air pressure actuated vacuum feedthrough.

Rotating Wire Scanner

For measurement of beam intensity profiles versus transverse coordinates. The intensity profile is measured by a wire which rotates inside the vacuum of a beam transport line. The wire detects particles directly or by measurement of the charge released by secondary electrons. The scan system itself is mounted to a CF-150 flange and can be attached directly to a standard diagnostic chamber.

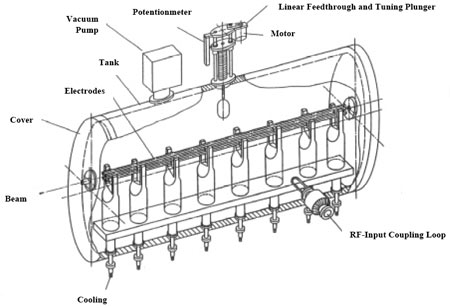

RFQ Accelerator Structures

Various RFQ structures of the 4-rod type. In addition, the subsequent services can be offered:

- Design and manufacturing of Rf-systems.

- Design and manufacturing of vacuum systems.

- Delivery of a control system via PC or VME for the systems mentioned. The control system includes all necessary hard- and software.

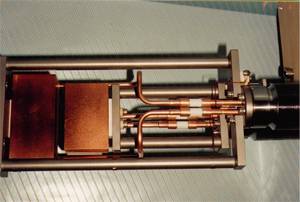

Jaw Slit Systems

Jaw slit systems available (with UHV-Feedthrough, Type LM 17) are used for beam size limitation, beam analysis functions, and energy definition in beam transport systems of particle accelerators. The slit-jaw system can consists of a cooled copper block which is covered with a tantalum plate. To facilitate good heat conductivity between copper and tantalum, a special vacuum braze has been chosen (SCP 3 AT, 930°C Degussa). To avoid tension between Ta jaw and Cu body components, a thin copper plate has been placed between the jaw and the body of system.