Interested in learning more?

Seamless Integration

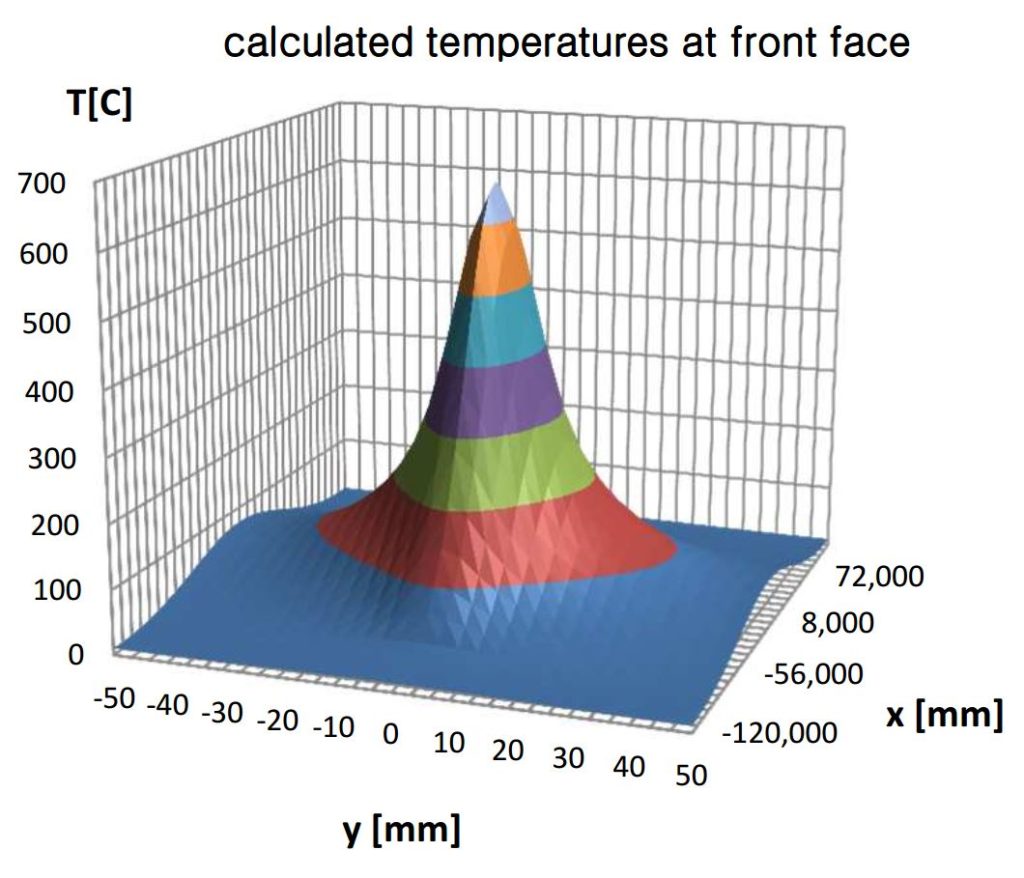

The principle of operation is rather simple: the ion beam is hitting a piece of metal, the current flow to earth is measured with an ammeter and corresponds to the beam current.

For practical implementation, however, there are a number of edge effects to consider:

The applications are very different, like our solutions. Please confront us with your specific wishes, name us your characteristic parameters such as the expected beam current, the particle species, the beam energy, the beam spot size and the required aperture, movable to linear drive or stationary. We will certainly find an optimized solution.

They are designed in 50 Ohm geometry. Even for high power applications with direct water cooling on the cup body we get high bandwidth. Impedance shift is compensated by geometrical adjustment. Again, provide us with your special requirements and beam parameters, we will offer a dedicated solution.

They form the physical end of the beam line. We integrate those on a flange. Size and exact execution depends on your requirements.