Interested in learning more?

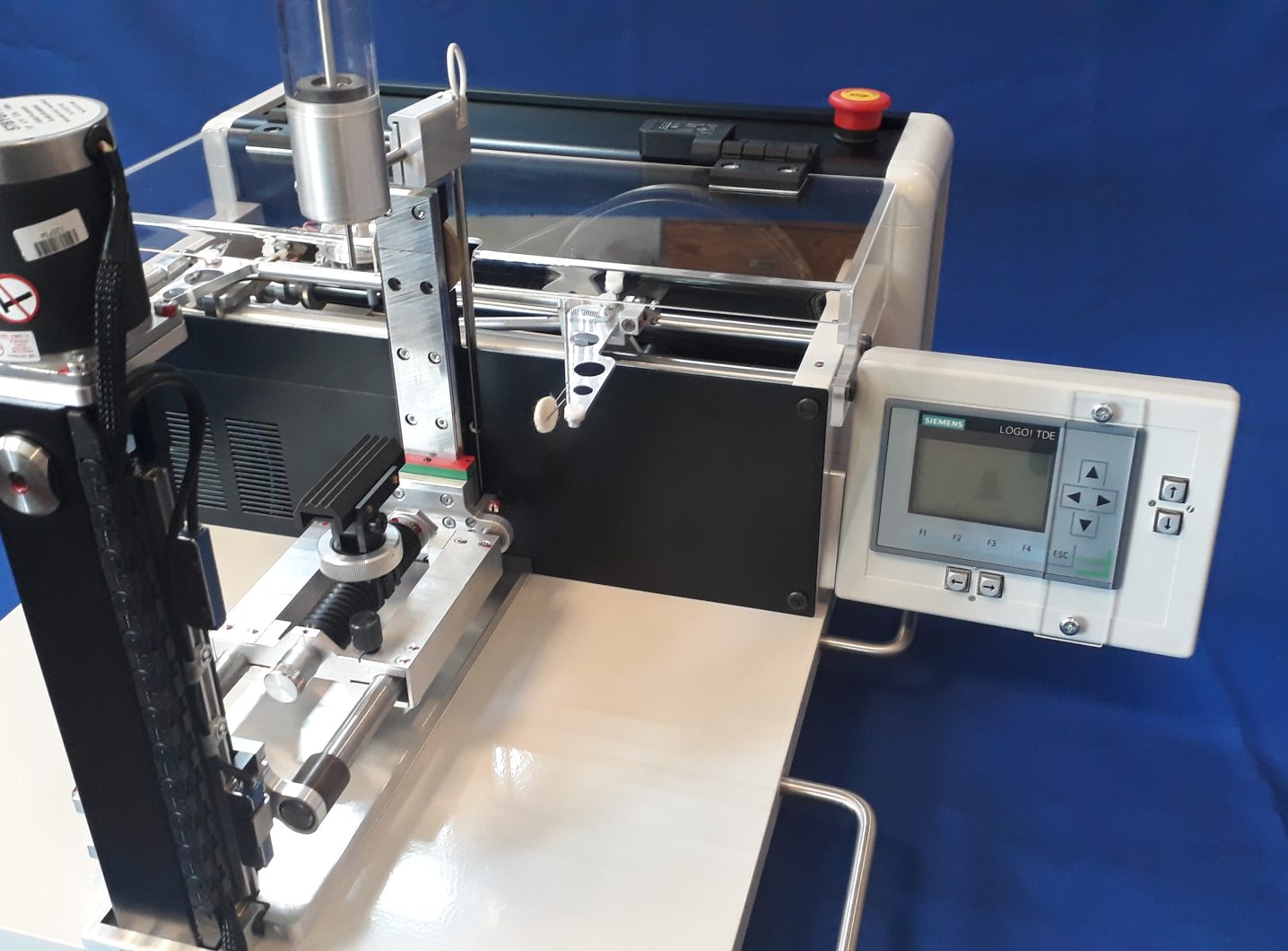

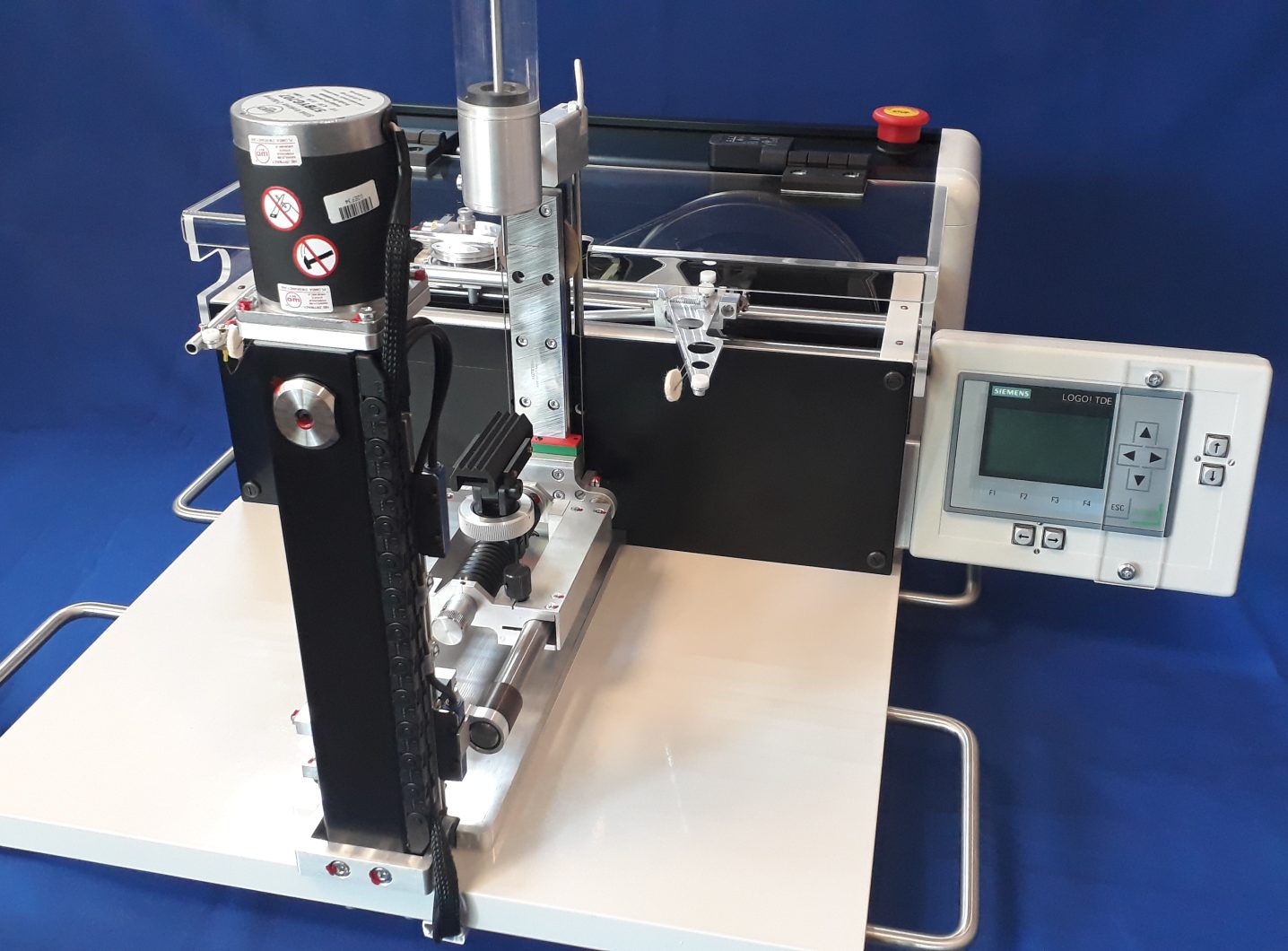

The WS25B Wire Saw is a precision device for cutting or slicing hard and brittle materials, such as metals, ferrites, ceramics, stones etc. In particular, it is useful for cutting semiconducting materials. The wire saw enables cutting of very thin slices (thickness of 10um) with smooth cut surfaces. This saw is recommended for cutting materials where losses of material should be minimized and cutting should not introduce crystal deformations or defects. The use of the special accessories (goniometers, orientation devices) extends the WS25B saw’s application to precision cutting of crystallographically oriented crystals. The WS25B Wire Saw enables cutting with two methods: the free cutting slurry method with tungsten wire for no-stress cutting (very important to save specimen material structure and not be destroyed) and cutting with a diamond dotted wire, which is a faster but more aggressive method suggested for cutting very hard materials.

Advantages

- Semi-automatic, requires no supervision

- Can cut semiconductors, ferrites, metals, glasses and other hard or brittle solids

- Minimized material losses (>30 um)

- Slices samples perfectly parallel

- No additional lapping required

- Can be used with accessories to extend the saw’s application in precision cutting

| Technical Data | |

|---|---|

| Sample Max. Dimensions | 80mm x 80mm, 150mm length |

| Power Supply | 220-250 V/50 Hz or 110 V/60 Hz |

| Wire Diameter | Tungsten wire diameter: 20-60 um Diamond dotted wire: 100-300 um |

| Wire Oscillation Frequency | 150-200/min |

| Weight | 68 kg |

| Dimensions | 630 x 720 x 250mm |