Interested in learning more?

Diamond Wire Saw – DWS.250

The DWS.250 type diamond wire saw is currently our largest two-way vertical table saw.

The maximum workpiece cutting area is 250×250 mm and the recommended diamond wire thickness is 0.20 to 0.50 mm. The continuously adjustable wire speed goes from 0 to 4 m/s. To ensure a constant cutting pressure, the feed is done by gravity. Workpieces can be cut both wet and dry.

The DWS.250 is equipped with an operator-guided, ergonomically visible touch control. There is currently a choice of six languages (DE-EN-FR-ES-JP-CN). The industrial-grade drive and control technology ensures robust and precise operation. The built-in sensor system for end of cut, open hood or, if necessary, wire breakage ensures safety. The precision saw is made of stainless steel and anodized aluminum.

On the slot table of the DWS.250 your workpieces can be fixed flexibly with our offered clamping devices.

Technical Data

| Saw Housing | |

|---|---|

| Type | Stainless steel -aluminum -construction |

| Safety | according to European directive |

| Saw dimensions | H 1050 x L 700 x W 450 mm |

| Saw weight | 85 kg |

| Drive / Power Supply | |

|---|---|

| Engine power | 120 Watt |

| Power supply | 100-240 V / 50-60 Hz |

| Diamond Wire | |

|---|---|

| Outer diameter | 0,2 - 0,5 mm |

| Wire length | 30 m |

| Drum diameter | 250 mm |

| Control System | |

|---|---|

| Operating interface | color touch panel |

| Security code protection | deactivatable |

| Separation | |

|---|---|

| Separation method | Diamond wire cut |

| Cutting pressure | Constant / gravity |

| Cutting speed | 0 - 4 m/s |

| Sample | |

|---|---|

| Max. sample weight | 20 kg |

| Sample dimension | 250 mm x 250 mm |

| clamping device | Clamping device |

| Wire Cleaning | |

|---|---|

| Kind | Mech. water swirling |

| Alternate | Dry or air jet |

Accessories

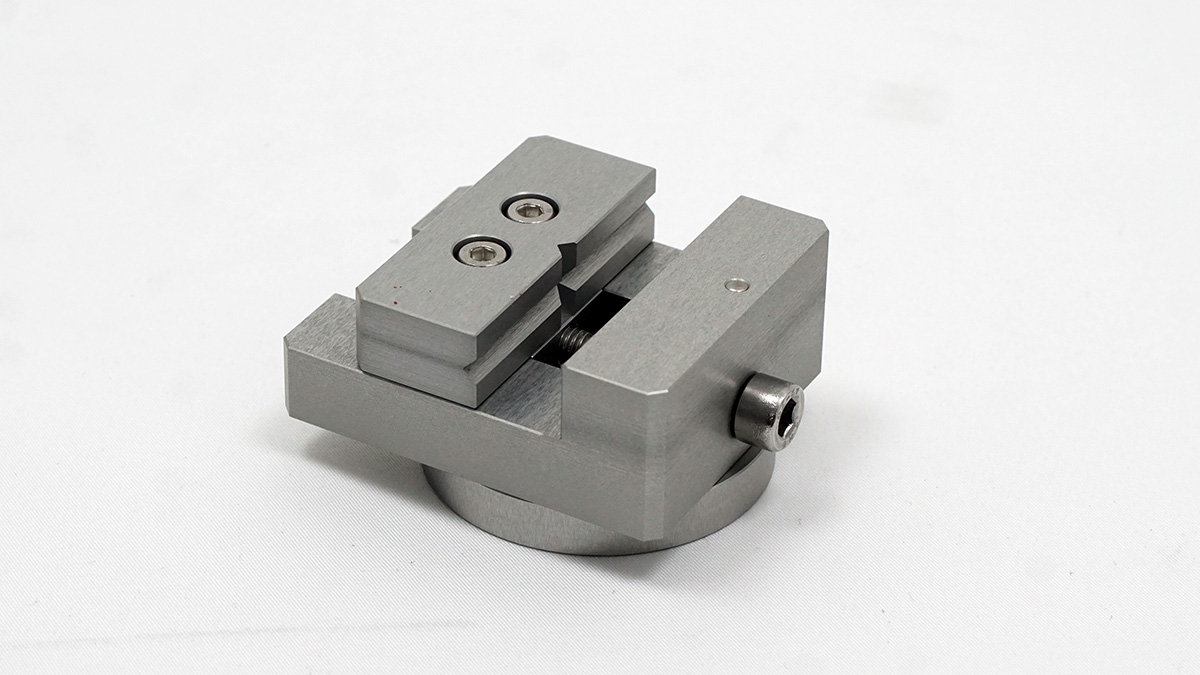

Adjustable Clamping Unit

Art. SE.XXX

Adjustable Stop

Art. AB.50

Built-In Micrometer

Art. EM.50

Carrier Disc / Ceramic

Art. TS.K

Carrier Discs / Aluminum

Art. TS.A

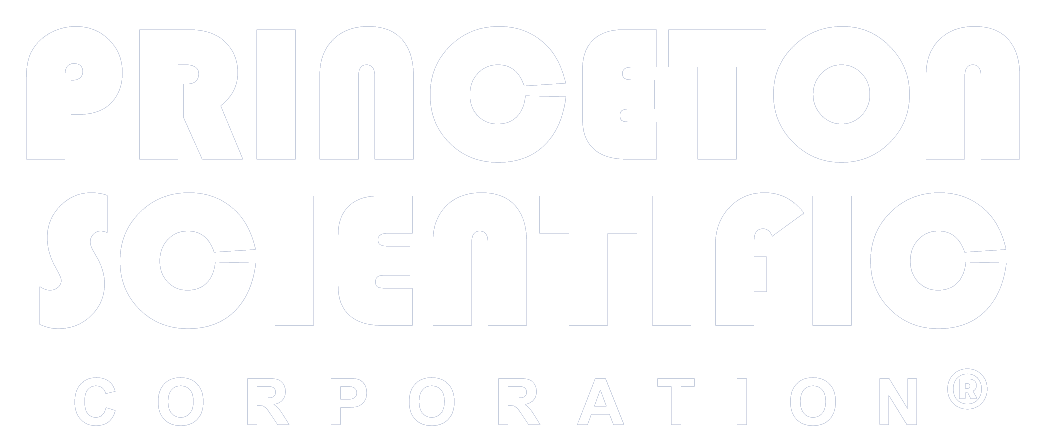

Clamping Block Set

Art. SB.180

Clamping Block Set (up to 110mm)

Art. SB.60

Clamping Set

Art. SP.58

Cutting Fluid

Art. SF.1

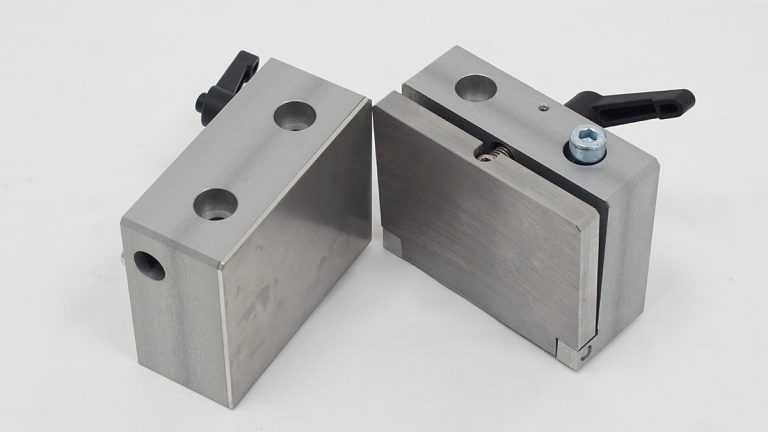

Frontal Sample Carrier

Art. FPT.50

Goniometers

Art. GPT.4

Grease Gun

Art. FP.60

Heating Plate

Art. HP.18

Horizontal Sample Carrier

Art. HPT.20/40

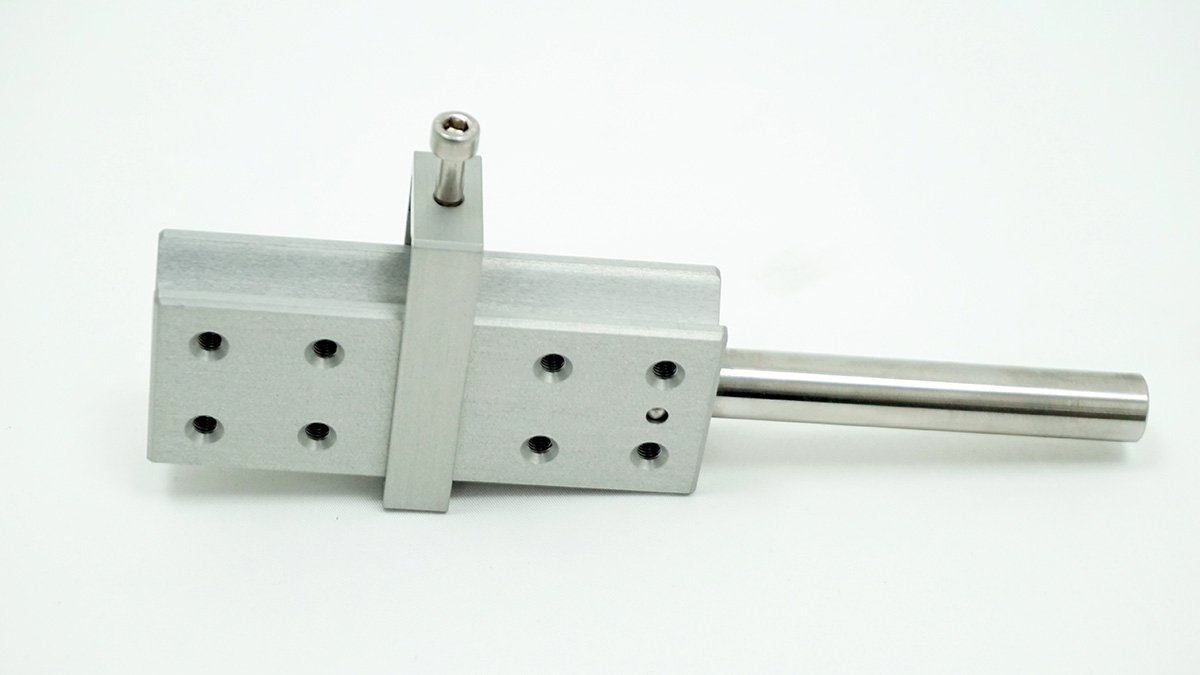

Machine Vice

Art. MS.150

Magnifying Lamp

Art. LL.400

Microloupe

Art. ML.30

Mini Vice

Art. MS.30

Potting Boxes

Art. GB.16

Potting Resin

Art. VH.1

Power Cleaner

Art. KR.50

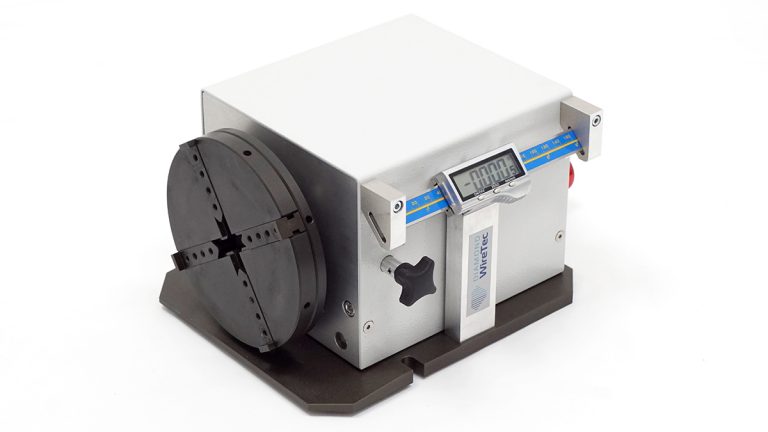

Rotary Table

Art. DT.50

Rotary Unit

Art. DE.130

Scraper Plate

Art. SP.200

Side Sample Carrier

Art. SPT

Signal Light

Art. SL.3

Special Wax

Art. SW.4

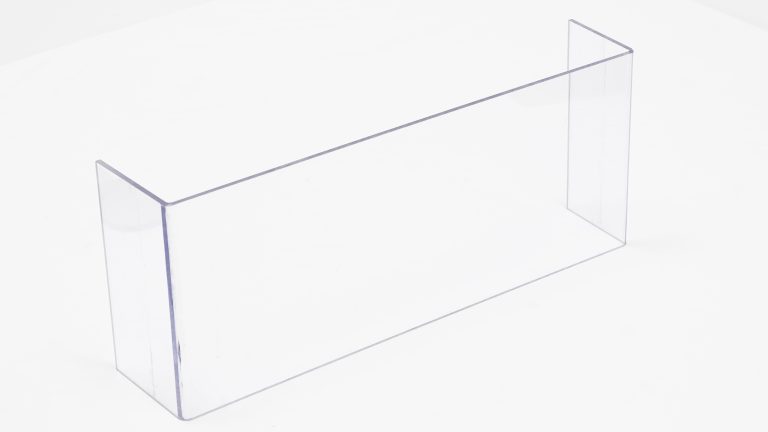

Spray Protection

Art. SP.XXX

Under Table

Art. UT.X