Interested in learning more?

We have a New Webshop!

Full of 1000’s of new products dedicated to High (and Ultra High!) Vacuum products and systems for your Research, Development, and Production needs.

Highest Quality Standards

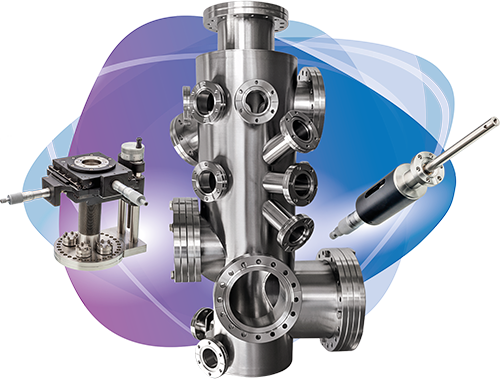

Princeton Scientific Corp. offers high-quality vacuum products and systems. We offer a wide selection of components for the introduction, handling, and manipulation of substrates, wafers, and other samples in ultra-high vacuum (UHV), high vacuum (HV), or other controlled environments.

UHV technology is a vast and ever-growing field of research that contributes to a wide array of industries. It is UHV technology that is leading the world to greater innovation and discovery. When your work is this important, it is crucial to know that you are receiving equipment of the highest quality and standards. Princeton Scientific’s mission is to supply this high-quality technology to companies and institutions like yours, so you can continue to do the work that is changing the world.

All of these devices are designed and built to the highest quality standards.

Please advise Princeton Scientific Corporation of your current or upcoming needs and we would be pleased to provide you with a solution and a very competitive offer!!

Please contact uhv@princetonscientific.com for questions or inquiries.

We have a New Webshop!

Full of 1000’s of new products dedicated to High (and Ultra High!) Vacuum products and systems for your Research, Development, and Production needs.

Chambers, UHV Valves & Accessories

- UHV Chambers Manufacturing

- UHV Leak Valves

- UHV Right Angle Valves

- Valve Accessories

- Gaskets

- Feedthroughs

- Ion Gauges

- Hinged Doors

- Port Aligners

Components

- CF, KF and ISO Flanges & Fittings

- Circular Miniature Feedthroughs

- Co-Axial Feedthroughs

- Power/High Voltage Feedthroughs

- Sub-Miniature D Feedthroughs

- Thermocouple Feedthroughs

- Triaxial Feedthroughs

- Fibre Optics

- Kapton Wires & Accessories

- Safety Components

- Gauges

- Viewport Accessories

- Special Custom Built Vacuum Equipment

We Can Provide Custom Engineering.

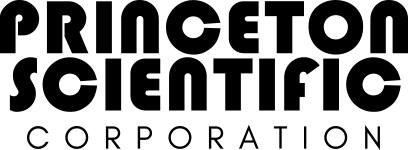

Bell-Jar Type Thermal Systems

Bell Jar type simple evaporator for day-to-day use. Up to four box style evaporators can be integrated. If needed, these can be dedicated for Zn, In, Cd, Ca, Pb evaporation, sequentially or to deposit any materials. Systems can be tailored to produce multilayered nanosized metallic oxide, fluoride and organic films. Standard features such as the thickness monitor and QCM sample rotation units can be comfortably utilized by the user. Typical cycle time for two-layer thin film coating experiment is about 1.5 hours. Base Pressure is 5×10-7 Torr.

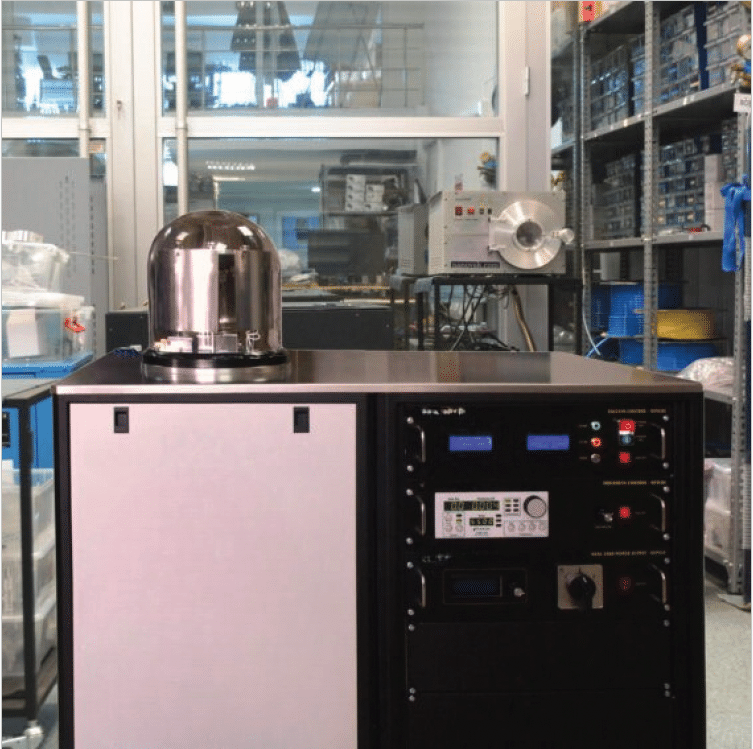

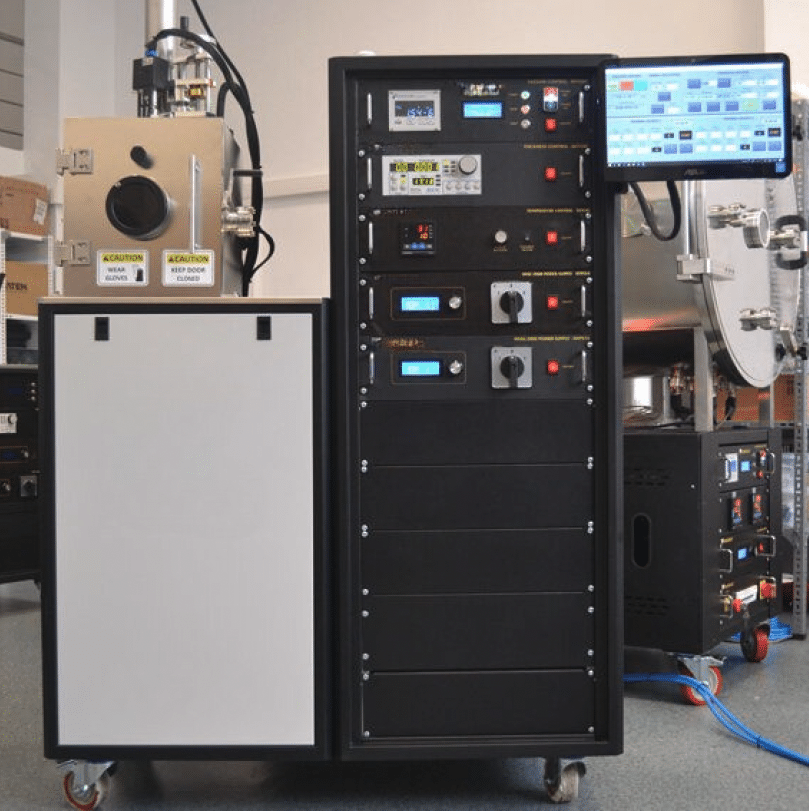

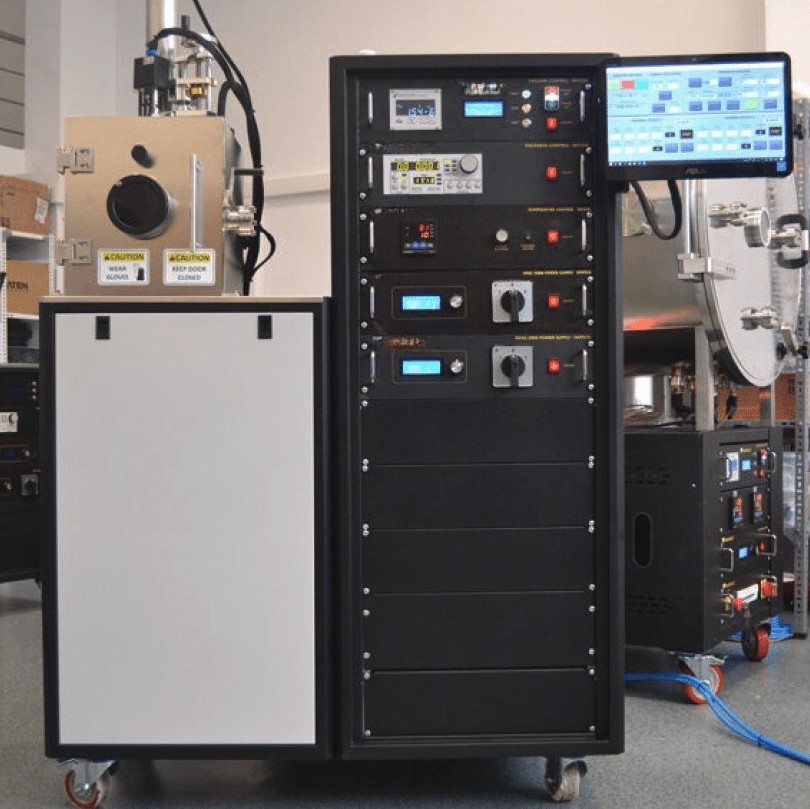

Load-Lock Equipped Coating Systems

Systems with Load-Lock chambers are preferable for faster processing and higher quality coating of products. Sample loading/unloading is done in the Load-Lock chamber. Transfer to the main chamber is performed using a magnetic transfer arm. Within our product range, Load-Lock enhancement is applicable to Thermal, Sputtering, E-Beam or HiPIMS type systems. It may be possible to complete the coating process in 10-7 Torr high vacuum cleanliness while loading a new wafer every 15 minutes with the Load-Lock setup.

E-Beam Systems

Water-cooled cylindrical/prismatic vacuum chambers are produced out of SS304 material. This system has 1-2 thermal and/or 6-crucible e-beam sources enabling the user to do full co-evaporation. Typical properties of the system can be given upon request. Multilayered thin films of different materials can be prepared. The system can be tailored to fit user needs to produce multilayered nanosized metallic oxide, carbide or nitride films.

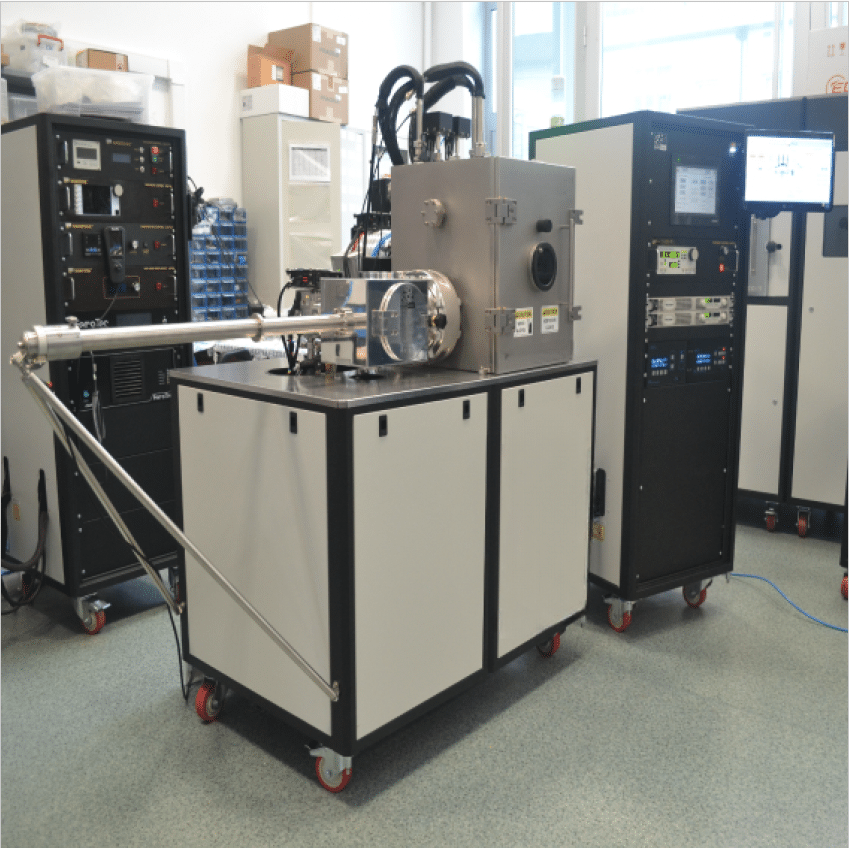

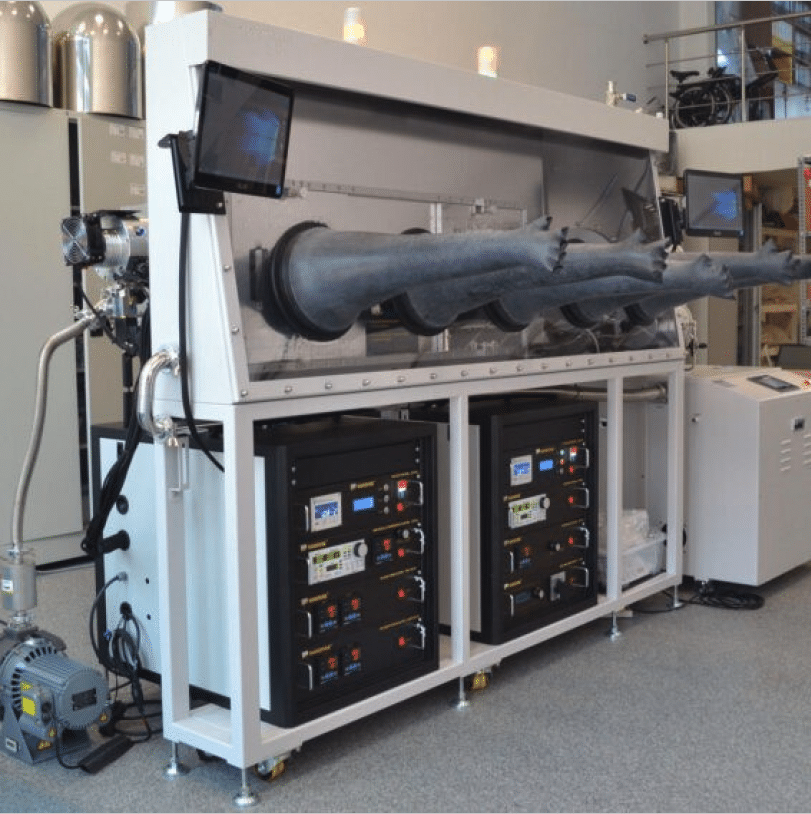

Glove-Box Adapted Vacuum Systems

PSC Glove-Box Systems combine Glove-Box units supplied by dedicated Glove-Box specialists and PSC vacuum and electronic components. These systems can be configured with one or two vacuum chambers with hinged doors in the back and sliding doors on the Glove-Box side. There are added components such as vacuum pumps and QCM units. Systems easily pump down to 1×10-7 Torr vacuum levels. Components such as thickness monitors, sputter guns, evaporation sources and effusion cells can be added. The chambers are e-polished on the inside and outside. Systems are configured to run automatically with tailored LabVIEW programs. The Glove-Box sustains 0.1 ppm water vapor and oxygen levels with its blower and filter apparatus.

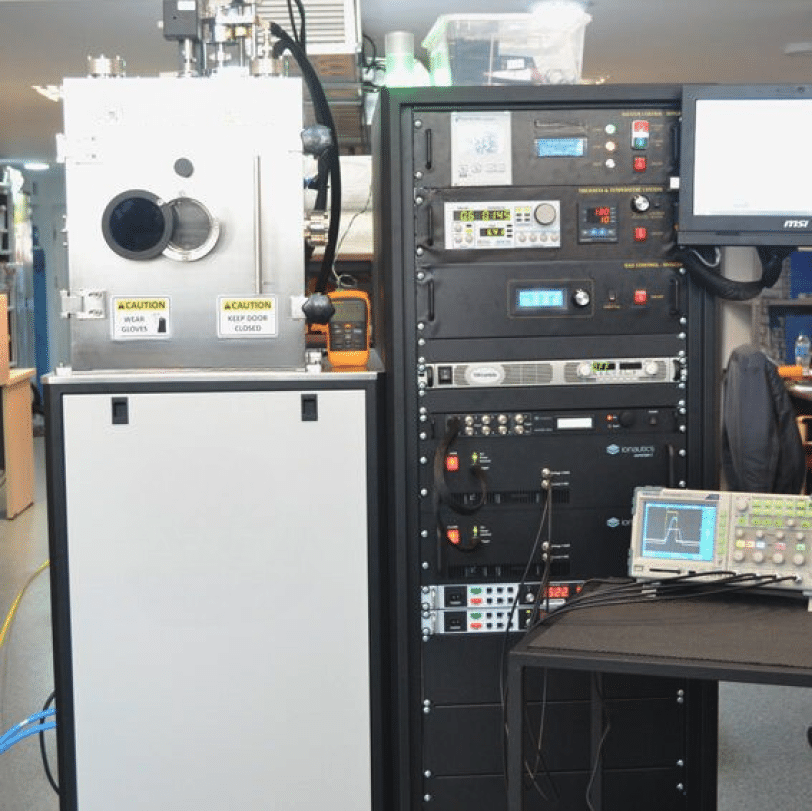

High Power Sputtering Systems

HIPIMS systems are based on high energy pulsed DC magnetron technology. In this method, 500-1000 VDC short duration pulses are sent to targets with 100-500 A/cm2 currents to generate very high ionization plasma density. Consequently, very dense, well-adhered, high-quality films can be obtained. Oxide and nitride films can also be made by HIPIMS reactive sputtering using metallic targets. The substrate holder can be biased to DC pulsed voltage with high accuracy synchronization to the target pulse. These systems can have up to 4 sputtering sources. Therefore, up to 4 multi-layered materials can be produced including nanosized metallic oxide, fluoride or nitride films.

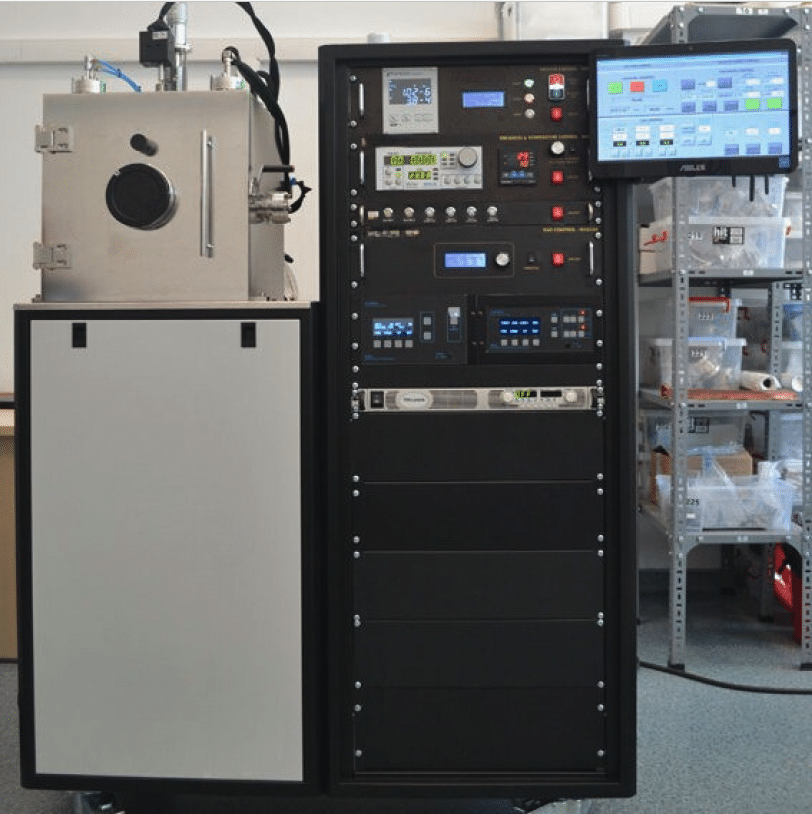

Magnetron Sputtering Systems

Box-type Physical Vapor Deposition systems are based on prismatic/cylindrical vacuum chambers. These systems have 1-4 DC/RF sputtering sources. Multi-layered thin films of 4 different materials can be prepared. The PSC Sputter System can be tailored to fit user needs to produce multilayered nanosized metallic oxide, carbide or nitride films, such as Ni, Fe, Au, Zr, Ti, Si, SiO2, ZnO, TiO2, Si3N4 and SiC, among others.

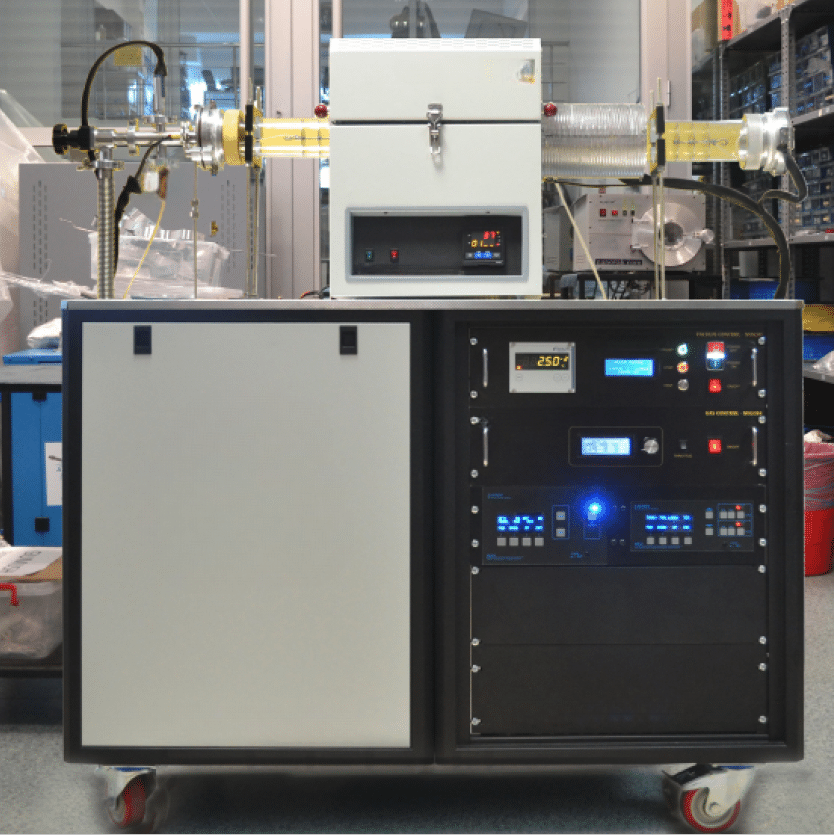

Plasma Enhanced Chemical Vapor Deposition

PSC has recently developed a PECVD (Plasma Enhanced Chemical Vapor Deposition) tube furnace system, which consists of a 300 W RF plasma source, optional split tube furnace, and 3 channel mass flow controller units for gases like Ar, H2, CH4. It is ideal for Graphene film production as well as TiN, TiC, SiC, Si3N4 films.

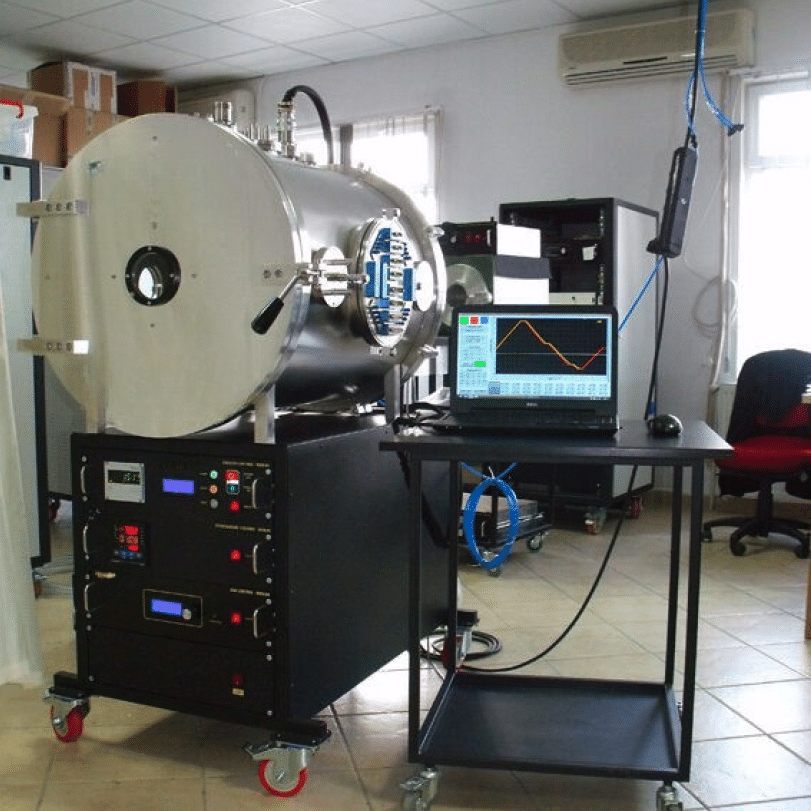

Space Simulator Systems

PSC has developed a space simulator system that enables the user to conduct vacuum, gas, and temperature-dependent experiments using a computer user interface. The chamber volume can be 200 – 1000 lt. and can house a thermal table which may be heated and cooled and may carry loads up to 100 kg. Base pressure level is 10-7 Torr and pressure can also be controlled by a leaking mixture of Ar, N2 and O2, H2 gases from 10-7 to 1000 mbar. The table can be cycled between -100 °C and +150 °C for long periods.

Thermal Evaporator Systems

This box type Physical Vapor Deposition system is based on prismatic/cylindrical vacuum chambers. These systems have 2 – 4 thermal sources. Multi-layered thin films of two, three or four different materials can be prepared, and the system can be tailored to fit user needs to produce multilayered nanosized metallic oxide, fluoride or nitride films, such as Si, Al, Ti, SiO, Au, Ag, WO, BaF2, and MgF2.

Thermal & Sputter Combined Systems

This box-type Physical Vapor Deposition system, based on prismatic/cylindrical vacuum chambers, has 2 thermal and/or 1-4 DC-RF sputter sources enabling the user to do full co-evaporation. Multi-layered thin films of different materials can be prepared, and the system can be tailored to fit user needs to produce multilayered nanosized metallic oxide, carbide or nitride films, such as Si, Al, Ti, SiO, WO, BaF2, MgF2, TiO2, Si3N4, SiO2, and TiN.

Vacuum Furnace & Bake-Out Systems

The Vacuum Furnace and Bake-Out System is produced out of SS304. The furnace can be used for outgassing & baking samples between 30 – 500 °C. Samples can be loaded vertically or horizontally. Various electrical feedthroughs can be added for real time monitoring of electronics. The PSC Vacuum Furnace and Bake-Out System can be tailored to fit user needs.